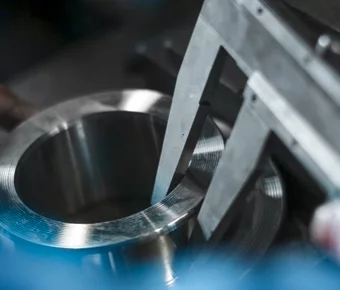

Machine shop

Fast and custom-made.

Whether turning, grinding, boring or sawing: Our machining centre not only offers many possibilities to bring steel products to measure. We also manufacture parts from solid material for you.

Machining

Reworking and adapting.

No problem for us.

We will process welded fittings and flanges for you – entirely according to your wishes and specifications. In this way, we offer you exactly the component solution you need. Of course including approval according to PED and AD-2000 W0 certificate. So that you can meet the market at all times.

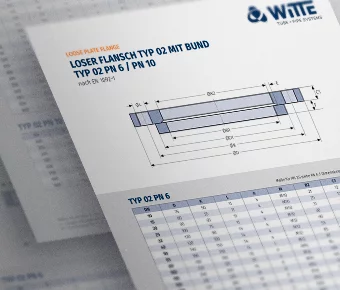

Manufacturing

Looking for a special part?

We will manufacture it for you.

Whether reducers, T-pieces, threaded or hexagonal parts – in addition to machining welded fittings and flanges, we will also manufacture individual parts and small batches with accuracy to 0.1 millimetres. Gladly also including approval and testing by works experts.

- Turning of the connection dimensions (S) – from ½“ to 8“

- Grinding of larger dimensions up to 16“

- Boring of the inner diameters – from ½“ to 8“

- Fitting of welding chamfers according to DIN 2559 F21/ F22 / ASME B16.25

- Sawing of elbows to any angle – from ½“ to 16“

- Surface treatment for flanges – Rz, Rth 0.5 – 160

- Axial grooving – for example tongue / groove

- Internal grooving

- Concentric and eccentric reducers from ½“ to 8“

- T-pieces from ½“ to 6“

- Threaded parts (welding nipples, double nipples, sleeves) from ½“ to 4“ – R, Rp, G, NPT

- Hexagonal parts (such as hexagonal plugs, hexagonal double nipples) from ½“ to 4“

- Manufacturing of individual parts and small series with accuracy to 0.1 mm

- Other parts according to drawing

- Conventional machine shop, enlarged from 266 sqm to approximately 713 sqm

- Currently Germany’s machine shop with the shortest delivery times for the metal cutting machining and manufacturing of fittings

- Conventional lathe for turning diameters above the bed of up to 1,000 mm

- Cycle-controlled lathe with a turning diameter of up to 570 mm above the bed for small batches

- Team of eight conventional machining technicians

- Approved manufacturer according to AD W0/PED

Approvals carried out by our works expert are possible at any time, as are any possible further tests/analyses carried out by an accredited test laboratory working for us.